The Modified Atmosphere Packaging (MAP) Tray Machine is key equipment in the food industry. It keeps food fresh by changing the air inside the package.

First, the machine removes the air from a sealed tray. Then, it fills the tray with a special mix of gases, like nitrogen and carbon dioxide.

This process stops bacteria from growing and prevents food from oxidizing. As a result, it greatly extends the food's shelf life without any need for chemical preservatives.Because of its excellent freshness protection, this machine is now the top choice for packaging fresh meat, ready-to-eat meals, and cut fruits and vegetables.

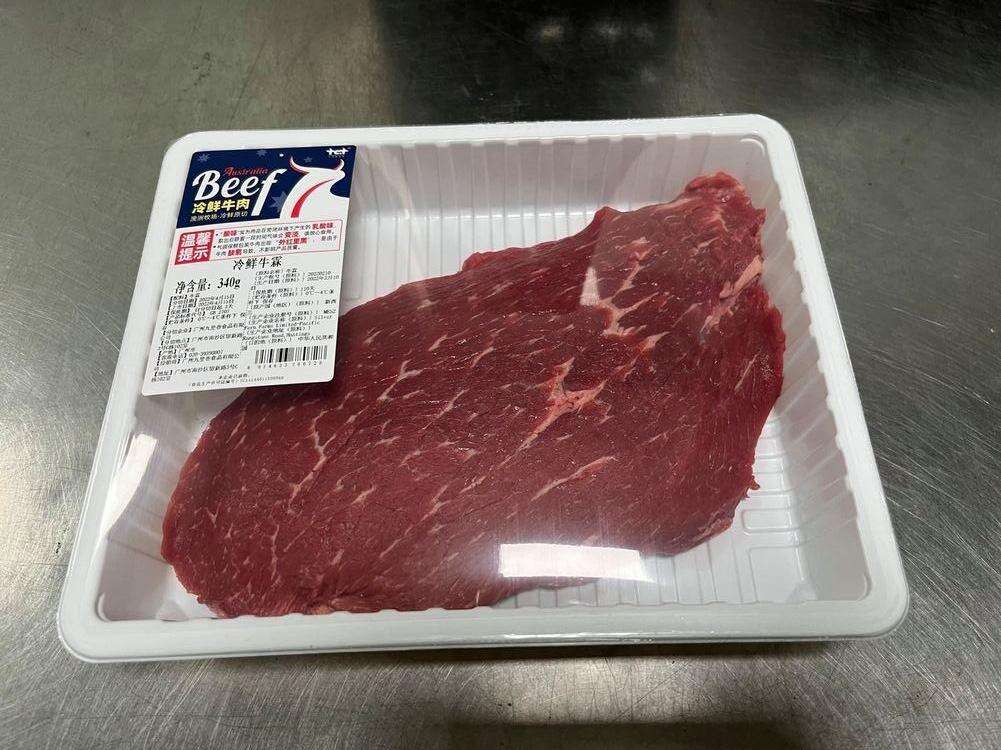

(MAP) is excellent for keeping fresh pork, beef, lamb, chicken, and duck fresh longer. It works by controlling the air inside the package. A small amount of oxygen keeps the meat a bright red color that customers prefer. At the same time, carbon dioxide in the package stops bacteria from growing and slows spoilage. Compared to ordinary plastic wrap trays, MAP can extend the shelf life of fresh meat by 1–2 times or more, improving both appearance and freshness.

Seafood products like fish fillets, shrimp, shellfish, and crab sticks are highly prone to spoilage due to their delicate texture and high unsaturated fat content, demanding advanced preservation techniques. Modified Atmosphere Packaging (MAP) offers an effective solution by precisely controlling the gas composition inside the package. This technology significantly inhibits the growth of seafood-specific spoilage bacteria such as Thiobacillus, extending freshness. Meanwhile, the optimized gas mix helps reduce liquid loss, maintaining a plump and fresh appearance that enhances product appeal. Additionally, MAP limits oxygen exposure, delaying fat oxidation and preventing off-odors, thereby preserving the natural flavor and quality of the seafood.

The prepared foods sector is growing rapidly, driven by the expansion of central kitchens and ready-to-eat meal markets, creating strong demand for professional packaging solutions. Modified Atmosphere Packaging (MAP) is widely used for cooked meats like marinated meats, roasted chicken, ham slices, and sausages; pre-made dishes such as Kung Pao Chicken, Yu Xiang Shredded Pork, and Curry Beef; as well as potato salad, green salad, and various cold dishes. This packaging technology effectively prevents flavor transfer and drying while maintaining the original taste and texture of the food. With its ready-to-eat or easy-heat convenience, MAP perfectly meets the retail needs of modern fast-paced lifestyles.

Fresh-cut produce represents a key application of modified atmosphere packaging (MAP) technology. This method is ideal for a variety of products including cut fruit platters, salad greens, carrot sticks, celery segments, and more. The packaging works by precisely controlling oxygen and carbon dioxide levels inside the package. This reduces the respiration rate of fruits and vegetables, effectively delaying their ripening and aging process. Additionally, the low-oxygen environment prevents cut surfaces (such as those of apples and potatoes) from browning by inhibiting polyphenol oxidase activity. The technology also helps minimize moisture loss, maintaining the natural crispness and freshness of the produce.

Modified Atmosphere Packaging (MAP) serves as an ideal preservation solution for various hard, semi-soft, and soft cheeses, as well as dairy products like yogurt puddings. By replacing the air inside the package with a protective gas mixture, MAP effectively inhibits mold growth—a common issue with cheese—while preventing the product from drying out, hardening, or absorbing unwanted odors. This technology helps maintain the original flavor and texture of dairy products, extending shelf life and ensuring consistent quality.

While Modified Atmosphere Packaging (MAP) costs more than regular packaging, it adds significant value to products. This technology helps make food items more premium and increases their overall worth.

MAP works by extending shelf life, locking in freshness, and maintaining the food's appearance and quality. This directly meets the needs of today's consumers, who look for high-quality, healthy, and convenient food options.

Although it requires a higher initial investment, MAP helps reduce food waste and supports a brand's premium image. This advantage helps products stand out in competitive markets and can lead to greater profit growth.

Hot News

Hot News