Tray Sealing Machine | TA350

The TA350 is our first tray sealing machine with MAP technology, fully developed by our team to meet market needs.

- Overview

- Recommended Products

Product Details

With support and feedback from thousands of users around the world, we’ve made the machine more stable and efficient. It now runs up to 12 cycles per minute. The MAP system helps keep food fresh by filling the tray with nitrogen in a steady and reliable way.

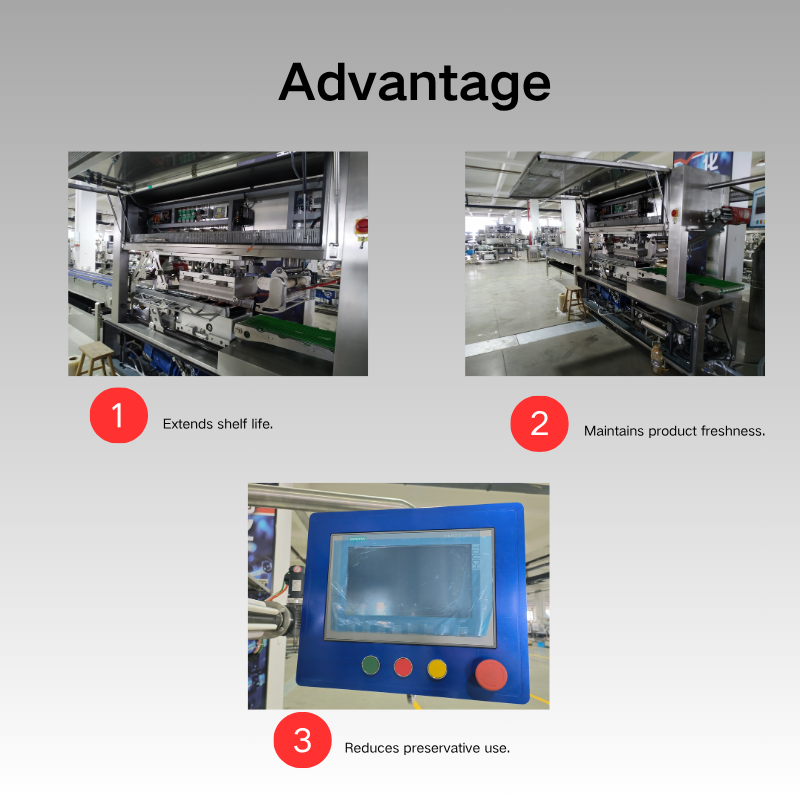

Product Advantages

Innovative Clamping Design

Uses 15–20% less film compared to traditional push-rod systems, helping reduce packaging costs.

Smart Control System

Our self-developed industrial-grade system features a full-color touch screen for precise and stable operation.

Full Food-Grade Stainless Steel Body

Made with seamless forming technology to meet CE hygiene standards.

Stable MAP Technology

Extends product shelf life by 2 to 3 times.

Smart Fault Detection

Helps lower maintenance costs with faster problem-solving.

Product Parameters

| Parameter | TA 350 | TA 360 | TA 750 |

|---|---|---|---|

| Maximum Mold Size | 620*380 millimeters | 760*380 millimeters | 1000*380 millimeters |

| Max. Speed | 48 trays/min | 60 trays/min | 60 trays/min |

| Tray Height | 10-120 millimeters | 10-120 millimeters | 10-120 millimeters |

| Sealing Width | 150-350 millimeters | 150-350 millimeters | 150-350 millimeters |

| Weight | 2000 kilograms | 2200 kilograms | 2700 kilograms |

| Size | 3950*950*2100 millimeters | 3950*950*2100 millimeters | 3850*850*2150 millimeters |

| Power Supply | Three phase 380V 50HZ 18KW | Three phase 380V 50HZ 18KW | Three phase 380V 50HZ 16KW |