The Labor Crisis Driving Packaging Machine Adoption

Why labor shortages are accelerating demand for packaging automation

The ongoing worker shortage crisis in manufacturing is completely changing how packaging works get done. According to Deloitte's numbers, around 2.1 million manufacturing jobs will still be empty by 2030, creating serious problems on factory floors everywhere. Traditional packaging machine lines need between 12 and 18 people working each shift just to handle basic stuff like setting up boxes, filling them, and sealing everything tight. Finding good workers for these roles has become next to impossible lately. Because of this constant lack of staff, more and more companies are turning to automated packaging solutions. These machines don't need coffee breaks, don't quit suddenly, and aren't affected by hiring freezes. They keep going nonstop, which means production stays steady even when nobody shows up for work. What we're seeing now isn't just about saving money on labor costs. It's really about staying in business at all as the old way of relying on human workers simply doesn't cut it anymore.

Industry data: Labor dependency vs. automation investment trends (2020–2024)

Investment patterns confirm this strategic shift. Packaging automation spending grew at an 11.3% CAGR from 2020 to 2024, while labor dependency metrics declined steadily:

| Year | Labor Dependency Index* | Automation Investment Growth (%) |

|---|---|---|

| 2020 | 100 (baseline) | 8.1% |

| 2022 | 87 | 9.7% |

| 2024 | 73 | 14.2% |

*Index measures direct labor hours per 10,000 units packaged (Source: PMMI 2024 Industry Report)

Manufacturers allocating more than 15% of CAPEX to packaging automation report 31% fewer labor-related disruptions. This correlation underscores how automation redefines production resilience—not by eliminating people, but by decoupling output stability from workforce volatility.

How Packaging Machines Directly Reduce Labor Dependency

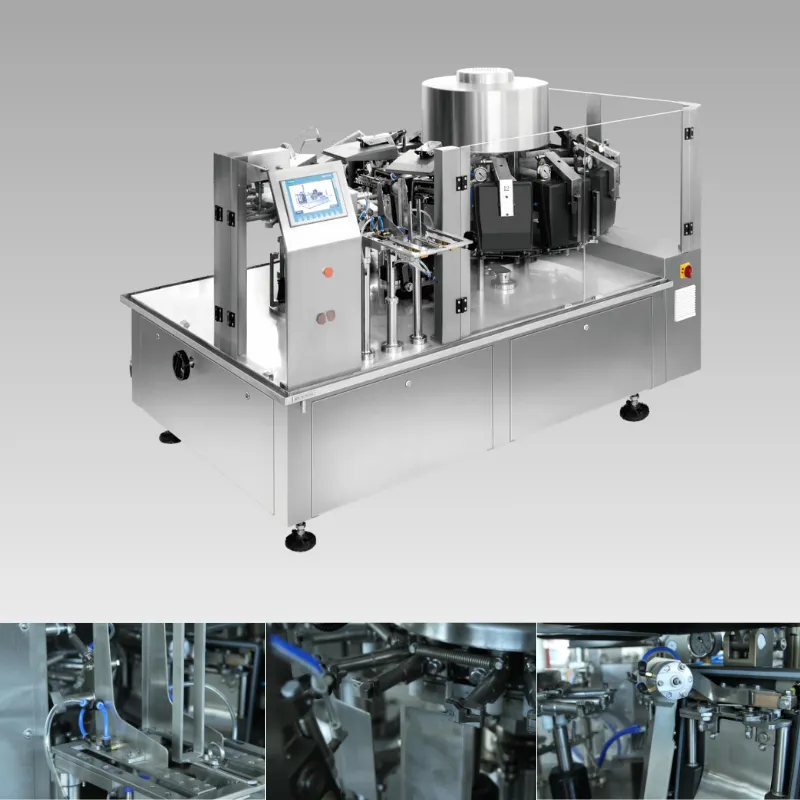

From manual packing lines to fully integrated packaging machine systems

Switching over from hand packing to automatic systems completely changes how work gets done on factory floors. Back in the day, employees spent their shifts doing all sorts of repetitive physical work sealing boxes, filling containers, applying labels, etc. Now these same jobs are handled flawlessly by machines that never get tired or make mistakes. Factories can run nonstop without worrying about workers getting fatigued or slowing down during long shifts. The whole setup has shifted too. Instead of having dozens of people working at individual stations, most operations now rely heavily on machinery for basic tasks while humans monitor several production lines from central control rooms. According to industry reports from PMMI, companies that install these integrated systems typically move around 60 percent of their previous packaging crew members into better positions within about a year. These include jobs related to quality checks, technical oversight, and fine tuning the automation systems themselves.

Quantified labor reduction: 35–42% fewer direct labor hours per shift

The numbers speak for themselves when it comes to packaging automation saving real money on labor costs. Across various industries from food processing to consumer goods manufacturing, companies have reported between 35% and 42% cuts in direct labor hours once they install complete packaging machine systems. Take a regular 40 hour workday for example. With automation, plants are seeing around 14 to 17 fewer man hours spent on packaging tasks. Why? Three main reasons stand out: machines just keep running at consistent speeds without stopping; there's no need for workers to switch between different tasks or wait for handoffs; and instead of needing 8 to 10 people packing manually, only 1 or 2 technicians can watch over several production lines at once. Recent data from a 2023 study on material handling backs this up showing automated lines hit about 97% runtime efficiency compared to just 74% for manual operations. What does all this mean? Plants get better productivity without sacrificing product quality or regulatory standards.

Beyond Headcount: Strategic Workforce Transformation with Packaging Automation

Reskilling frontline staff for supervision, maintenance, and data monitoring of packaging machines

Packaging automation isn't about replacing workers but rather changing how they contribute to the production line. Smart manufacturers are investing in retraining their front line employees so they become tech experts who can monitor operations, handle predictive maintenance tasks, and read through live performance metrics from packaging equipment. This approach helps fill critical skills shortages across areas like mechatronics, robot programming, and understanding digital systems, all while making jobs more satisfying and reducing turnover rates. According to PMMI's 2024 report, companies that establish proper training programs see around 30% better productivity from their teams, plus fewer unexpected stoppages and quicker problem solving when issues arise. When factories turn basic packers into knowledgeable operators and maintenance personnel, they create a workforce that adapts quickly to new challenges. The combination of human judgment and machine capabilities leads to ongoing improvements in efficiency and quality throughout the manufacturing process.

ROI and Operational Resilience: Measuring the True Value of Packaging Machine Investment

Third-party analysis shows packaging machine investments typically achieve payback within 18–24 months through direct labor savings alone—with high-uptime configurations reducing unplanned downtime risk by up to 65%. But the full value extends far beyond headcount reduction:

- Enabling rapid production scaling during demand surges—without recruitment delays or onboarding lag

- Cutting human error—related product waste by 30–47% annually

- Delivering real-time operational data for predictive maintenance, avoiding $740,000 in annual losses tied to line stoppages (Ponemon Institute, 2023)

Tech workers who've been retrained to handle several automated production lines can triple their output compared to traditional setups. For plant managers looking at return on investment, there are three main factors worth considering: how steady the production flow remains, whether products meet quality standards consistently, and what gets lost when relying too much on hands-on workforces, particularly when finding good staff becomes tough. What really stands out as a major benefit? Factories running automated systems maintain over 98.5 percent stable output even when faced with serious personnel issues. This means orders still get shipped on schedule, safety regulations stay intact, and contracts remain honored despite all sorts of market ups and downs that would cripple less prepared operations.

FAQ

What is causing the current labor shortage in packaging?

The labor shortage in packaging is primarily due to an overall lack of available workers and difficulties in filling traditional roles given current market conditions.

What are the potential benefits of investing in packaging automation?

Investing in packaging automation can lead to labor cost savings, increased productivity, reduced human error, and a more stable production output.

How quickly can a business see returns from packaging machine investments?

Typically, businesses can achieve payback from packaging machine investments in 18–24 months through direct labor savings alone.

Does automation mean eliminating jobs entirely?

Automation does not mean eliminating jobs; rather, it reallocates roles, reskilling workers for supervision and maintenance of automated systems.

How do packaging machines help in reducing labor dependency?

Packaging machines automate repetitive tasks, allowing operations to become more efficient and less dependent on manual labor, thereby reducing the need for a large workforce.

Table of Contents

- The Labor Crisis Driving Packaging Machine Adoption

- How Packaging Machines Directly Reduce Labor Dependency

- Beyond Headcount: Strategic Workforce Transformation with Packaging Automation

- ROI and Operational Resilience: Measuring the True Value of Packaging Machine Investment

-

FAQ

- What is causing the current labor shortage in packaging?

- What are the potential benefits of investing in packaging automation?

- How quickly can a business see returns from packaging machine investments?

- Does automation mean eliminating jobs entirely?

- How do packaging machines help in reducing labor dependency?