Understanding Packaging Machine Customization Requirements

Why Standard Packaging Machines Fall Short for Non-Standard Products

Standard packaging machines often struggle with anything that doesn't fit neatly into their expectations. These machines were built for those neat rectangular boxes we see everywhere, but what happens when faced with something different? Tapered medical devices get squished, delicate ceramics crack, and everything ends up jammed somewhere along the line. Why? Well, most systems come with fixed molds, conveyor belts that won't budge, and sealing mechanisms that work great for standard stuff but fall apart with anything unusual. A recent study from Packaging Digest found that about 78 out of every 100 damaged products happen because companies try to force non-standard items through machines they weren't meant for. The consequences aren't just extra trash in landfills either. More returns mean more costs, and worse still, customers start questioning quality control. For high-end products or those under strict regulations, this kind of problem can really hurt a company's reputation over time.

Key Drivers of Customization: Geometry, Material Sensitivity, and Volume Flexibility

Three interrelated factors drive the need for bespoke packaging machinery:

- Geometry: Irregular shapes—such as spherical electronics or multi-tiered food containers—require adaptive tooling like CNC-guided arms or modular forming stations that reconfigure without downtime.

- Material Sensitivity: Temperature-sensitive substrates (e.g., biodegradable films) demand precision-controlled heat zones, while abrasive industrial parts necessitate reinforced contact surfaces to prevent wear-induced contamination.

- Volume Flexibility: Seasonal spikes or limited-run luxury goods benefit from throughput-adjustable systems—avoiding costly overcapacity while maintaining responsiveness.

Manufacturers implementing these targeted customizations report 40% faster changeovers and 30% higher line efficiency compared to retrofitting standard equipment.

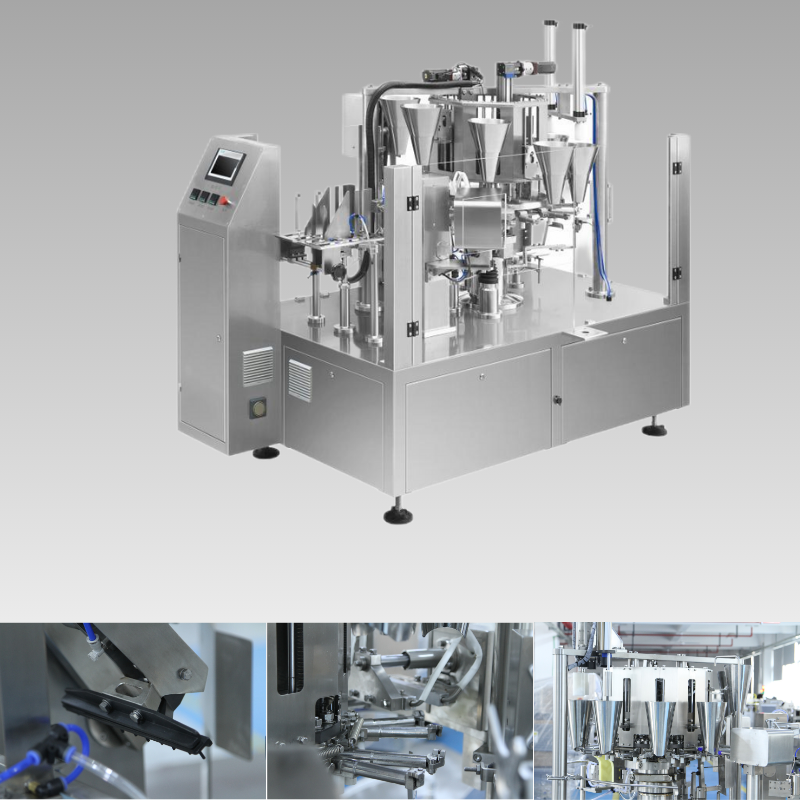

Customizing Packaging Machines for Complex Product Shapes

Adaptive Tooling Solutions: CNC, Laser, and Modular Forming for Irregular Geometries

Packaging those odd shaped or delicate items? Rigid tooling just gets in the way most of the time. CNC systems can hit around 0.1mm accuracy when making custom wire forms that protect things like medical implants and expensive electronics. Then there's laser forming which works without touching anything, so no need to constantly switch out tools. Great for changing seasons or quick prototypes really. The modular heads let operators switch from cube shapes to round ones or mix them together pretty fast. Packaging Digest reported about 35% quicker setup times last year actually. And these smart sensors built into the machines keep pressure under 5 psi when handling stuff like fancy lattice candy structures or fragile glass containers. That means nothing gets smashed while still keeping production moving at good speeds.

| Tooling Type | Key Advantage | Application Example |

|---|---|---|

| CNC Systems | ±0.1mm dimensional accuracy | Medical implant trays |

| Laser Forming | Contactless processing | Aerogel cushion packaging |

| Modular Toolheads | <10-minute changeover | Multi-format cosmetic jars |

Balancing Speed and Precision: Throughput Optimization in Shape-Specific Packaging Machine Configurations

When dealing with large volumes of complex shaped items, smart coordination matters more than just going fast. Servo driven conveyors work alongside optical sensors to keep things running smoothly about 95% of the time for those tricky ceramic pieces, adjusting space between items and their positions as needed. For parts that get slippery during transport, vacuum grippers help hold everything steady so nothing slips off track. The way motion is controlled makes a big difference too. Systems that spread control across multiple points boost production rates by around 22% compared to older central control methods, especially good for curved products. Smart computer programs watch how dense materials become in real time, particularly important for stuff like molded fibers. When these materials pack in more than 0.3 grams per cubic centimeter, the system slows down automatically to avoid getting stuck. Putting all these elements together creates a setup that can grow with demand while still keeping accuracy levels high and machines lasting longer.

Enabling Multi-Material Compatibility in Packaging Machines

Thermoform-Fill-Seal (TFS) Adaptation for Diverse Substrates: XLPE, EVA, PU, and EPP

TFS systems need to adjust properly for different types of plastics. Take XLPE with its stretchiness, EVA that works well in cold temps, PU which comes in various weights, and EPP known for absorbing impacts. Each material needs specific heat settings and pressure levels to prevent problems like layers peeling apart, parts warping, or weak seals. Getting this right depends on having tools that can swap out easily and heating sections that adjust themselves based on how thick the material is, usually within about half a millimeter difference. The system also relies on smart controls that get input from sensors during production. These controls tweak the sealing process automatically as things change, so manufacturers maintain good product quality while keeping up with production speeds even when switching between different materials.

Barrier Film Strategy: Integrating Tyvek, Foil, and Multilayer Aluminum into Packaging Machine Workflow

When working with high performance barrier films like hydrophobic Tyvek, aluminum foil, and various multilayer laminates, special care is needed to avoid problems such as tearing, tiny pinholes forming, or material breaking down from heat exposure. Good packaging equipment typically includes adjustable tension rollers along with low friction guides specifically designed for these sensitive materials. For sealing foil layers, many manufacturers now prefer ultrasonic technology instead of traditional heat based methods because it helps maintain the integrity of the barrier properties. Inline oxygen transmission rate sensors check how well seals hold up during production runs that can reach speeds around 120 cycles per minute. This testing ensures products meet strict standards regarding shelf life and sterility, something absolutely critical when dealing with things like medicines and medical devices where contamination risks are simply unacceptable.

FAQ Section

-

Why are standard packaging machines not suitable for non-standard products?

Standard packaging machines are designed for regular shapes and may damage or not efficiently handle irregular, delicate, or special-shaped products due to their fixed molds and rigid mechanisms.

-

What are the benefits of customizing packaging machines?

Customized machinery allows for better handling of irregular shapes, enhances processing efficiency, and supports diverse material compatibility, reducing damage rates and improving production precision.

-

What technologies aid in adaptive tooling for packaging machines?

Technologies like CNC, laser forming, and modular toolheads provide accurate, contactless, and quick-change capabilities for better adaptability to varying product shapes.

-

How do packaging machines ensure multi-material compatibility?

Machines are equipped with adjustable settings for heat and pressure and feature sensors and smart control systems that adapt to different materials, ensuring integrity and quality during production.