From Manual to Fully Automated Premade Pouch Machines and Sealing Machines

Switching from old school manual work to automated premade pouch machines has really changed the game for flexible packaging industries. Back in the day, workers had to fill each pouch by hand while carefully controlling the sealing settings, which meant production was painfully slow at around 15 to 20 units every minute. Today's automated systems can crank out over 400 pouches per minute with almost no defects, thanks to advanced servo feeding mechanisms and accurate volume fillers. A recent study on packaging efficiency from 2024 showed some impressive results too. Plants that went fully automated reported cutting their labor expenses by about 40 percent and saw output quality improve by nearly 30% when compared to those still using semi-automated equipment.

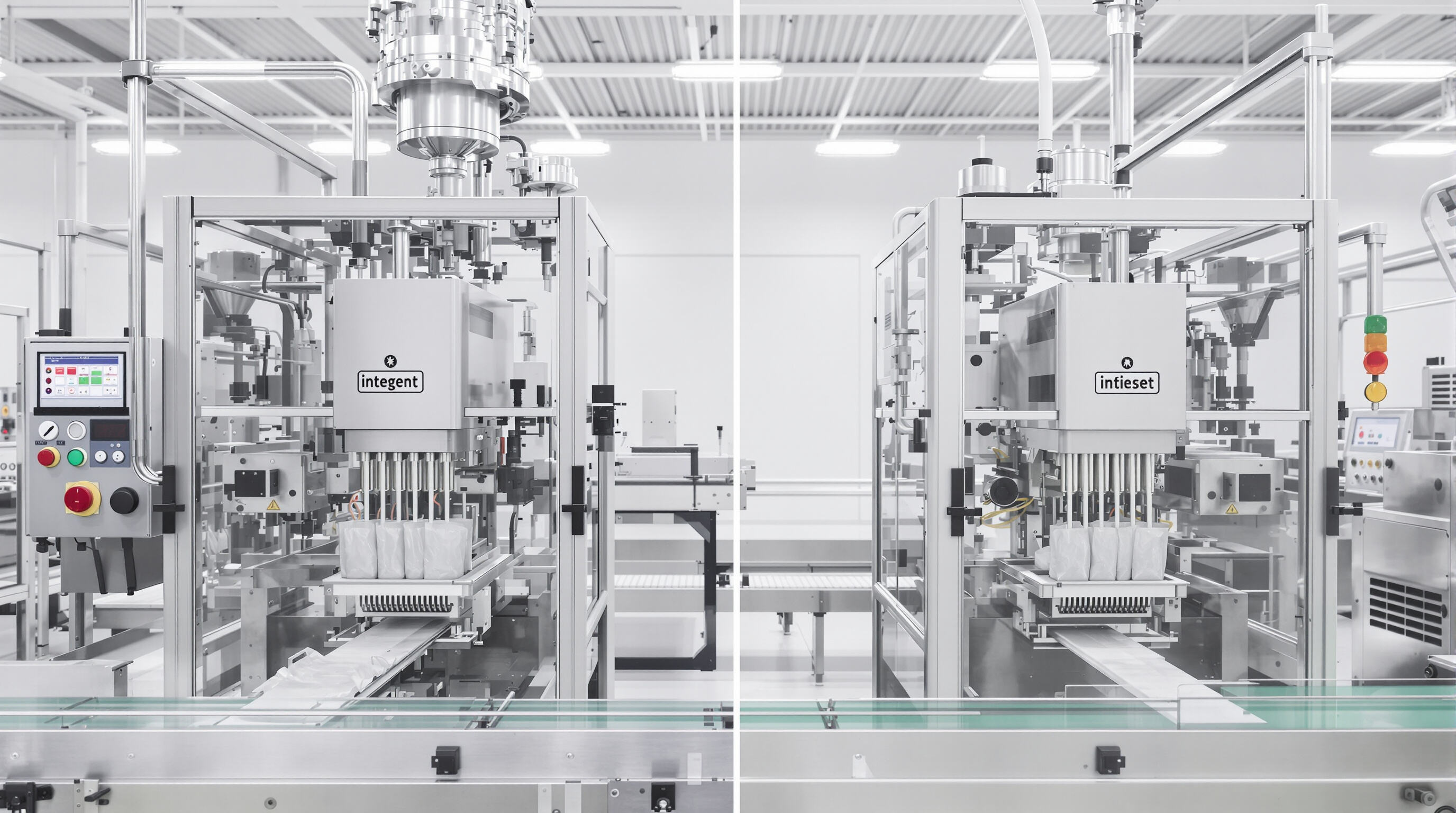

The Role of ECHO Machinery Co., Ltd. in Advancing Premade Pouch Technology

ECHO Machinery Co., Ltd stands at the forefront of flexible packaging solutions, bringing some pretty impressive tech to market. Take their dual-track pouch handling system for instance it cuts down on those pesky changeover times by around two thirds, which makes production lines run much smoother. Recently they've been working on something called self adjusting seal jaws too. This tech basically adapts to different material thicknesses within about plus or minus 0.2 millimeters, so when there are fluctuations in moisture levels during sealing processes, we see roughly a third fewer failures happening. What this means for manufacturers is real progress against some tough problems facing the industry right now keeping seals intact across all sorts of film combinations used both in food packaging and pharmaceuticals where quality control matters most.

Integration of Smart Controls and Sealing Technologies in High-Speed Operations

New generation premade pouch machines now come equipped with IIoT controllers capable of tracking over 120 different parameters as they happen. These include things like film tension ranging between 2 to 15 Newtons and seal bar temperatures anywhere from 130 to 200 degrees Celsius. The whole system works on collecting all this data so it can predict when parts might fail. Smart AI software actually spots signs of wear long before anything breaks down, sometimes giving warning signals more than three days in advance. According to a recent 2025 report on smart factories, facilities that have adopted these advanced systems are seeing impressive results too. They manage to keep their operations running smoothly about 92% of the time, which beats traditional production lines by nearly 18 percentage points.

Key Performance Metrics in Modern Premade Pouch Machines

| Metric | Traditional Machines | Intelligent Machines | Improvement |

|---|---|---|---|

| Cycle Time | 0.8 sec/pouch | 0.35 sec/pouch | 56% faster |

| Changeover Duration | 45–90 minutes | 8–15 minutes | 82% reduction |

| Energy Consumption | 12 kW/h | 7.2 kW/h | 40% savings |

| Material Waste | 4.2% of input | 1.1% of input | 74% less |

These advancements enable manufacturers to align with tightening sustainability regulations while meeting rising demand for customized pouch formats in e-commerce and grab-and-go retail segments.

Digital Transformation in Packaging: Industry 4.0 and Real-Time Intelligence

How Automation Is Reshaping Efficiency in Pouch Packing Processes

Premade pouch machines today can run cycles about 23% quicker thanks to those fancy servo-driven automations. This cuts down on how much humans need to check things like fill accuracy which stays within about half a milliliter difference, plus makes sure seams hold up properly. According to some recent numbers from the Flexible Packaging Alliance in their 2024 report, facilities that paired these pouch systems with robotic palletizers saw production jump by around 18%, all while saving 14% on energy costs. Big name manufacturers are now rolling out these PLC controlled motion setups that tweak sealing pressure as materials pass through, adjusting on the fly based on actual thickness measurements. For snack foods especially, this has slashed seal problems by roughly 92%, making waste management a whole lot easier for factory managers dealing with rejected products.

Smart Packaging and Industry 4.0 Integration with Premade Pouch Machines

The convergence of IoT-enabled sensors and edge computing allows premade pouch machines to self-optimize production parameters. For example, hybrid systems combining vision inspection with cloud-based analytics automatically adjust film tension during high-speed operations (150+ pouches/minute). This Industry 4.0 integration enables:

- Remote recipe management across global production sites

- Self-diagnosing thermal sealers that predict electrode wear 72+ hours before failure

- Energy consumption tracking down to individual sealing jaws

Real-Time Monitoring and Predictive Maintenance for Maximum Uptime

Since implementing continuous OEE tracking through SCADA systems back in 2022, pharmaceutical pouch production lines have seen a significant drop in unexpected downtime - around 41% reduction overall. The vibration analysis modules now catch those pesky motor bearing issues at just 0.02mm deviation points, which makes them roughly six times better at spotting problems compared to what we used before. Facilities that adopted AI for detecting anomalies are experiencing something remarkable too. Critical parts such as the servo-driven film advance systems last much longer between breakdowns, with plants reporting an impressive 98.6% uptime between failures on these essential components.

Case Study: Digital Twin Implementation in a High-Volume Premade Pouch Line

One cosmetics company based in Europe saw their format changeovers speed up by around 34% when they started using a digital twin of their pouch production line. Their virtual model spotted issues with compressed air systems that were holding them back at just 110 pouches per minute. After making some adjustments, they managed to push this number up to 144 pouches per minute without needing any new equipment. These days, production managers run tests on different packaging materials within the digital twin first, which saves them from wasting resources on failed physical prototypes. This approach has cut down on R&D waste by roughly two thirds each year according to internal reports.

Sustainability Innovations in Premade Pouch Machinery

Meeting Sustainable Packaging Demands Through Machine Adaptability

Today's premade pouch machines can handle almost any material these days, around 98% of them work great with both recyclable and biodegradable films. This is really important as countries worldwide are slowly getting rid of those single use plastic products we all know so well. According to that recent Korea Packaging Market Report from 2024, about three quarters of manufacturers are now looking specifically for equipment that works with plant based laminates and those simpler mono material structures. What makes this so valuable for companies is they don't need to spend extra money on new tools when switching between different materials like paper aluminum combinations or those compostable PBAT films that have become increasingly popular lately.

Reducing Material Waste via Precision Sealing Technologies

Advanced laser-guided sealing systems achieve 0.2mm accuracy in pouch seams, reducing film waste by 18% compared to traditional heat bars. Integrated vision systems automatically adjust sealing parameters for ultra-thin eco-friendly materials (τ50µ), preventing overcompensation that typically adds 5–7% excess material usage.

Energy-Efficient Designs in Modern Premade Pouch Machines

Latest models feature regenerative braking systems that recover 35% of motion energy from vertical form-fill-seal mechanisms. Variable-frequency drives optimize motor loads during batch production, cutting idle power consumption by 52% while maintaining 200+ pouches/minute output. These innovations reduce total energy expenditure to 0.11 kWh per 1,000 units—a 63% improvement since 2020.

Modular and Flexible Configurations for Customized Production Needs

Scalable Premade Pouch Machine Setups for Diverse Product Lines

Today's ready-made pouch machines come with modular setups that make it much easier to scale up operations as needed. The plug and play parts work together through standard connections, so factories can adjust their production lines within just a few hours instead of waiting days. This really matters when dealing with different products like those tiny packets of ketchup versus big bags for medicine. Traditional fixed systems aren't so flexible. With these modular options, companies can gradually expand their production without throwing out all their existing machinery every time they want to enter a new market segment.

Rapid Changeover and Format Flexibility in Modular Systems

Leading-edge premade pouch machines achieve format changeovers in under 15 minutes through auto-adjusting sealing jaws and tool-free component swaps. This agility stems from three innovations:

- Motorized positioning systems that calibrate pouch dimensions digitally

- Universal mounting plates accommodating diverse filling nozzles

- AI-assisted recipe management for instant parameter adjustments

Such flexibility helps manufacturers achieve 98%+ uptime while running short batches, according to 2023 packaging line efficiency studies.

Trend Analysis: Rising Demand for Customization in Flexible Packaging

Personalized packaging has really taken off lately, causing demand for those flexible premade pouch machines to jump about 42% since 2021 according to the Global Packaging Trends Report. Companies are looking for equipment that can handle all sorts of special requests these days - think limited edition designs, seasonal stuff, and even pouches tailored for specific regions without slowing down production too much. What's interesting is how this fits right into what we're seeing across manufacturing overall. With Industry 4.0 becoming more common, having modular systems means factories can tweak their production lines on the fly based on actual sales numbers and what consumers are actually buying at any given moment.

Balancing Speed and Sustainability: The Next Frontier in Premade Pouch Machine Performance

Today's premade pouch machines can produce around 400 packages every minute with sealing consistency hitting about 99.3% according to PMMI data from 2024. This shows that being green doesn't have to come at the expense of production speed. The latest improvements include laser guided filling nozzles which cut down on wasted products by roughly 8% each time they run thanks to their incredibly precise control at the micron level. Meanwhile, smart vision systems powered by artificial intelligence catch even tiny seal issues as small as 0.2mm right away, so we don't end up wasting materials on defective pouches that would otherwise need to be thrown away.

A recent analysis reveals 23% of manufacturers still prioritize speed over eco-designs, but innovators are bridging this gap with:

| Metric | High-Speed Systems | Sustainable Designs | Balanced Approach |

|---|---|---|---|

| Energy Use/Pouch | 18 Wh | 12 Wh | 14 Wh |

| Material Waste Rate | 2.1% | 0.9% | 1.4% |

| Avg. Line Downtime | 6.8 hr/month | 3.2 hr/month | 4.1 hr/month |

This data-driven optimization allows leading manufacturers to reduce annual carbon emissions by 740 metric tons without sacrificing output. Hybrid sealing technologies now enable 30-second format changes, ensuring rapid adaptation to recyclable or biodegradable films while maintaining operational speeds above 400 ppm.

Frequently Asked Questions (FAQ)

What are premade pouch machines used for?

Premade pouch machines are used for filling and sealing pre-formed pouches in various industries, including food packaging, pharmaceuticals, and more.

How have premade pouch machines evolved over time?

Premade pouch machines have evolved from manual operations to fully automated systems with smart controls and intelligent sealing technologies, improving efficiency and reducing waste.

What role does ECHO Machinery Co., Ltd play in the development of premade pouch technology?

ECHO Machinery Co., Ltd is a leader in flexible packaging solutions, introducing technologies such as dual-track pouch handling and self-adjusting seal jaws for improved production efficiency.

How do smart controls and sealing technologies enhance premade pouch machines?

Smart controls and sealing technologies enable real-time monitoring, predictive maintenance, and improved production efficiency, reducing downtime and energy consumption.

What impact does Industry 4.0 have on pouch packing processes?

Industry 4.0 integration with premade pouch machines enables smart packaging and real-time intelligence, enhancing production efficiency and customization capabilities.

Table of Contents

- From Manual to Fully Automated Premade Pouch Machines and Sealing Machines

- The Role of ECHO Machinery Co., Ltd. in Advancing Premade Pouch Technology

- Integration of Smart Controls and Sealing Technologies in High-Speed Operations

- Key Performance Metrics in Modern Premade Pouch Machines

- Digital Transformation in Packaging: Industry 4.0 and Real-Time Intelligence

- Sustainability Innovations in Premade Pouch Machinery

- Modular and Flexible Configurations for Customized Production Needs

- Balancing Speed and Sustainability: The Next Frontier in Premade Pouch Machine Performance

- Frequently Asked Questions (FAQ)