Understanding the Environmental Impact of Chocolate Packaging Machine

Common Packaging Materials and Their Environmental Footprint

Chocolate packaging typically uses multi-material designs, with 72% of global producers relying on plastic-aluminum laminates (43% market share) and paperboard composites (29%). These combinations pose significant environmental challenges due to limited recyclability and long decomposition times.

| Material | Decomposition Time | CO2e per Ton | Recycling Rate |

|---|---|---|---|

| Plastic Laminate | 450+ years | 3.8 tons | <14% |

| Waxed Paperboard | 2—5 months | 1.2 tons | 68% |

| Biopolymer Films | 8—12 weeks | 2.1 tons | 94% (compost) |

Aluminum-based wrappers contribute to 23% of chocolate’s supply chain emissions despite high recyclability potential, primarily because they are difficult to separate in mixed-material laminates, according to a 2025 packaging trends analysis.

Plastic Pollution in the Chocolate Industry: Key Data and Trends

Chocolate companies dump around 840,000 metric tons of plastic garbage every year. Imagine laying all that plastic out flat - it would wrap around the equator nearly 1.7 times! Most of this waste comes from those shiny single-use wrappers we tear open when buying candy bars, plus all those fancy rigid boxes for gifts during holidays. The problem gets worse because tiny bits of plastic from these packages contribute to 12 percent of the plastic pollution floating in our oceans across the Northern Hemisphere. Scientists have even found wrapper fragments in almost 7 out of 10 sea salt samples they tested recently. Pretty concerning stuff for something as simple as enjoying a chocolate bar.

Industry Benchmarks for Waste Reduction in Food Packaging

Manufacturers at the top of their game who've adopted cutting edge chocolate packaging technology are seeing real results. They're saving between 40 and 52 percent on materials thanks to smart innovations like AI optimized films that cut down polymer usage by almost a third (around 19-28%), plus dynamic seals that stop excess packaging when cocoa butter gets messy. These improvements aren't just theoretical either - continuous monitoring systems have slashed rewrap rates dramatically, going from 8.2% all the way down to just 1.4%. According to data from the Sustainable Packaging Coalition, most major chocolate companies are already ahead of schedule on their waste reduction goals. About seven out of ten leading brands hit or surpassed the 2030 target of cutting waste by 45%, mainly because they switched to single material packaging solutions and invested in better machinery across the board.

Sustainable Packaging Alternatives Using Agricultural Byproducts

Cocoa Shells and Husks as Raw Materials for Eco-Friendly Packaging

The processing of cocoa beans leaves behind plenty of husks and shells as waste material. These contain around 58% cellulose according to research from Biocomposites Institute back in 2023. What's interesting is these byproducts can actually be turned into useful products like molded cushioning materials, biodegradable films, and even coatings that resist moisture. Putting this waste to good use means we don't have to extract new resources and significantly reduces carbon emissions too. Some recent work looking at sustainable packaging solutions showed something pretty impressive. When using cocoa based materials instead of traditional plastic films for wrapping chocolate bars, the carbon footprint dropped by about three quarters compared to regular PET films. That kind of reduction makes a real difference when considering environmental impact across the entire supply chain.

Bioplastics from Cocoa Waste: Technologies and Scalability Challenges

Despite their potential, only 22% of cocoa-processing facilities currently operate bioplastic conversion systems (Global Bioplastics Report 2023). Major hurdles remain:

| Challenge | Current Status | Target (2025) |

|---|---|---|

| Fiber separation efficiency | 68% yield | 85% yield |

| Production cost per ton | $2,150 | $1,700 |

| Heat resistance | 95°C max | 125°C required |

Scaling these technologies requires collaboration between chocolate producers and packaging machine developers to ensure compatibility with high-speed production lines.

Biodegradability Claims vs. Real-World Composting Infrastructure

According to a recent study from the Composting Consortium in 2024, most so-called compostable chocolate wrappers don't actually decompose properly in backyard compost bins. The numbers are pretty shocking really - about three quarters of them just sit there without breaking down. And it gets worse when we look at different parts of the world. Cities across Europe seem better equipped for this stuff, with around two thirds accepting industrial compostables. But over here in America, only about one in eight municipalities will take these materials. Things get even trickier in many developing countries where acceptance rates drop below five percent. These differences highlight why we need better certification standards that actually match what happens in real garbage disposal systems rather than idealized scenarios.

Chocolate Packaging Machine Innovations for Minimizing Material Waste

Precision Sealing and Film Optimization Technologies

Modern chocolate packaging machines reduce material use by 20—35% through laser-guided sealing and real-time dimension sensing. Thin-film optimization algorithms calculate the minimum viable thickness for protective barriers, cutting polymer usage by an average of 28% (Packaging Digest 2023). Millimeter-precise tension controls eliminate excess film previously used as buffer zones.

Role of Automation in Reducing Overuse of Packaging Materials

Automated packaging machines equipped with AI vision systems reduce film waste by 18% compared to manual setups by adapting to irregular shapes like truffles. Integrated load sensors optimize box sizing, reducing corrugated material use by 22% per shipment. Lines using automation also report 15% fewer packaging errors, minimizing rewraps.

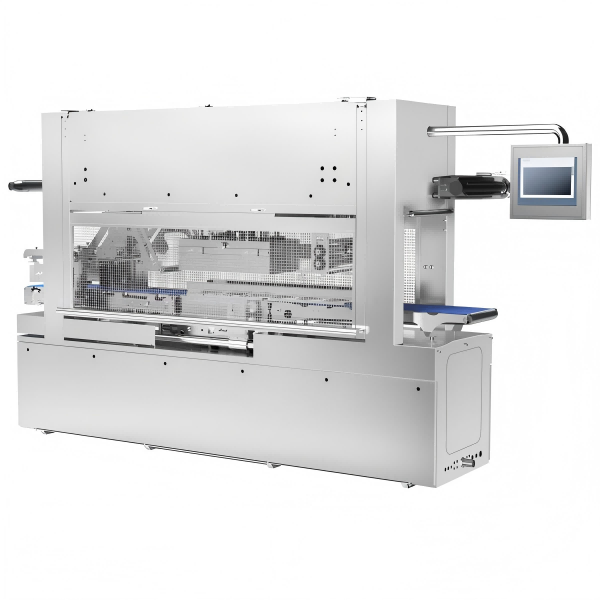

Case Study: ECHO Machinery Co., Ltd’s Low-Waste Packaging Systems

The adaptive film system from ECHO Machinery has slashed plastic usage by around 41 metric tons each year on 12 different production lines. This impressive reduction comes from three main improvements. First, they introduced variable nozzle dispensers that apply adhesive material only exactly where it's actually needed. Second, their energy recovery sealing heads cut down on wasted heat during startup periods. And third, they implemented a reel to reel recycling process for all the trim waste generated during forming operations. What makes these changes particularly attractive is the modular nature of the system. Manufacturers can retrofit this technology onto existing machines instead of having to replace entire production lines, which speeds up implementation while keeping costs manageable for most facilities.

Building a Circular Economy in Chocolate Manufacturing

From Waste to Resource: Closing the Loop in Chocolate Production

According to the 2024 International Circular Economy Report, leading manufacturers now repurpose 92% of cocoa processing waste—husks, pods, and shells—into packaging substrates and bioenergy. This closed-loop model diverts 2.1 million metric tons of agricultural waste from landfills annually and has reduced industry-wide virgin plastic use in chocolate packaging by 38%.

Waste Valorization: Turning Cocoa Byproducts Into Packaging and Energy

Innovations now allow cocoa husk fibers to replace 40—60% of plastic in chocolate wrappers without compromising shelf life. The residual organic matter fuels co-generation plants at production sites, reducing reliance on fossil fuels by up to 65% (Clean Energy Transition Institute 2024).

Integrating Circular Principles With Supply Chain and Packaging Design

Frontrunners deploy adaptive packaging machines that adjust film thickness based on ambient humidity, reducing material use by 22% (Packaging Science Review 2023). Blockchain-enabled data sharing helps 78% of manufacturers trace waste streams and identify circular reprocessing opportunities within 72 hours, improving responsiveness across the supply chain.

Real-World Success: Sustainable Packaging Strategies from Leading Chocolate Brands

Tony’s Open Chocolate: Zero-Waste Packaging and Ethical Innovation

Tony’s reduced plastic use by 92% through reusable paper wraps and plant-based inks. Its modular bar molds minimize packaging volume while preserving freshness, achieving a 40% reduction in packaging weight versus industry averages.

Divine Chocolate’s Shift to Recyclable and Compostable Materials

Divine replaced laminated foils with home-compostable cellulose films in 85% of its product range. A proprietary cocoa butter-resistant barrier coating derived from agricultural waste ensures an 18-month shelf life—addressing a key limitation of compostable materials in moisture-sensitive applications.

Lindt & Sprängli’s Sustainable Packaging Journey: Progress and Gaps

Lindt’s shift to 100% recyclable paper packaging for select lines eliminates 740 metric tons of plastic annually (2025 Chocolate Packaging Trends Report). However, only 23% of its total portfolio currently meets recyclability standards, highlighting ongoing challenges in scaling sustainable solutions for premium chocolates requiring oxygen and moisture barriers.

FAQs

What are the environmental challenges associated with chocolate packaging?

Chocolate packaging often involves multi-material designs, such as plastic-aluminum laminates and paperboard composites. These materials pose environmental challenges due to their limited recyclability and long decomposition times.

How do bioplastics from cocoa waste address packaging waste issues?

Bioplastics from cocoa waste can be converted into eco-friendly packaging materials by utilizing cocoa husks and shells, which significantly reduce the carbon footprint compared to traditional plastic films.

What is the role of automation in reducing packaging waste?

Automation in chocolate packaging machines reduces material waste by optimizing box sizing, minimizing film waste, and decreasing packaging errors compared to manual setups.

How are leading chocolate brands adopting sustainable packaging solutions?

Leading chocolate brands like Tony's and Divine Chocolate are implementing sustainable packaging strategies by using recyclable, compostable, and reusable materials, significantly reducing plastic use.

Table of Contents

- Understanding the Environmental Impact of Chocolate Packaging Machine

- Sustainable Packaging Alternatives Using Agricultural Byproducts

- Chocolate Packaging Machine Innovations for Minimizing Material Waste

- Building a Circular Economy in Chocolate Manufacturing

- Real-World Success: Sustainable Packaging Strategies from Leading Chocolate Brands

- FAQs