Smart Tech Integration in Food Bagging Machines

AI vision systems are revolutionizing food packaging by automating quality control through advanced defect detection. Using cameras and neural networks, these systems identify contaminants, sealing flaws, and packaging defects at speeds exceeding 120 packages per minute while continuously improving accuracy through machine learning - reducing false rejects by 40-60%.

IoT Connectivity in Food Packaging Operations

Networked sensors create interconnected packaging systems that enable proactive decision-making. Temperature-controlled baggers automatically adjust settings based on environmental conditions, reducing food spoilage by 25-30%. These smart systems generate optimized maintenance schedules through OEE tracking. A comprehensive analysis of IoT-driven packaging automation confirms these operational benefits.

Machine Learning for Adaptive Packaging Processes

Self-optimizing algorithms dynamically recalibrate filling weights and bagging speeds based on real-time product analysis. Machine learning models handle material variations, yielding 30-45% faster changeovers while maintaining packaging integrity through predictive tension control.

Robotics Automation in Food Bagging Systems

Modern food bagging operations implement robotics to enhance precision and throughput. Robotic systems process up to 50% more units hourly than manual lines while reducing human error. Their adaptability allows quick recalibration between product formats, making them ideal for facilities managing diverse SKUs.

Collaborative Robots for Flexible Packaging Lines

Collaborative robots (cobots) work safely alongside humans, adjusting grip strength in real-time to handle fragile items like chips - reducing waste by 18%. Their plug-and-play interfaces enable redeployment across stations within 30 minutes, ideal for seasonal product shifts. Force-limited joints ensure OSHA-compliant worker safety while maintaining output consistency.

Automated End-of-Line Packaging Solutions

Robotic palletizers and case packers achieve 99.7% load stability compliance with millimeter accuracy. Vision systems align cartons automatically, cutting labor requirements by 65% in case-packing operations while optimizing material usage - a critical sustainability advantage as distribution costs rise.

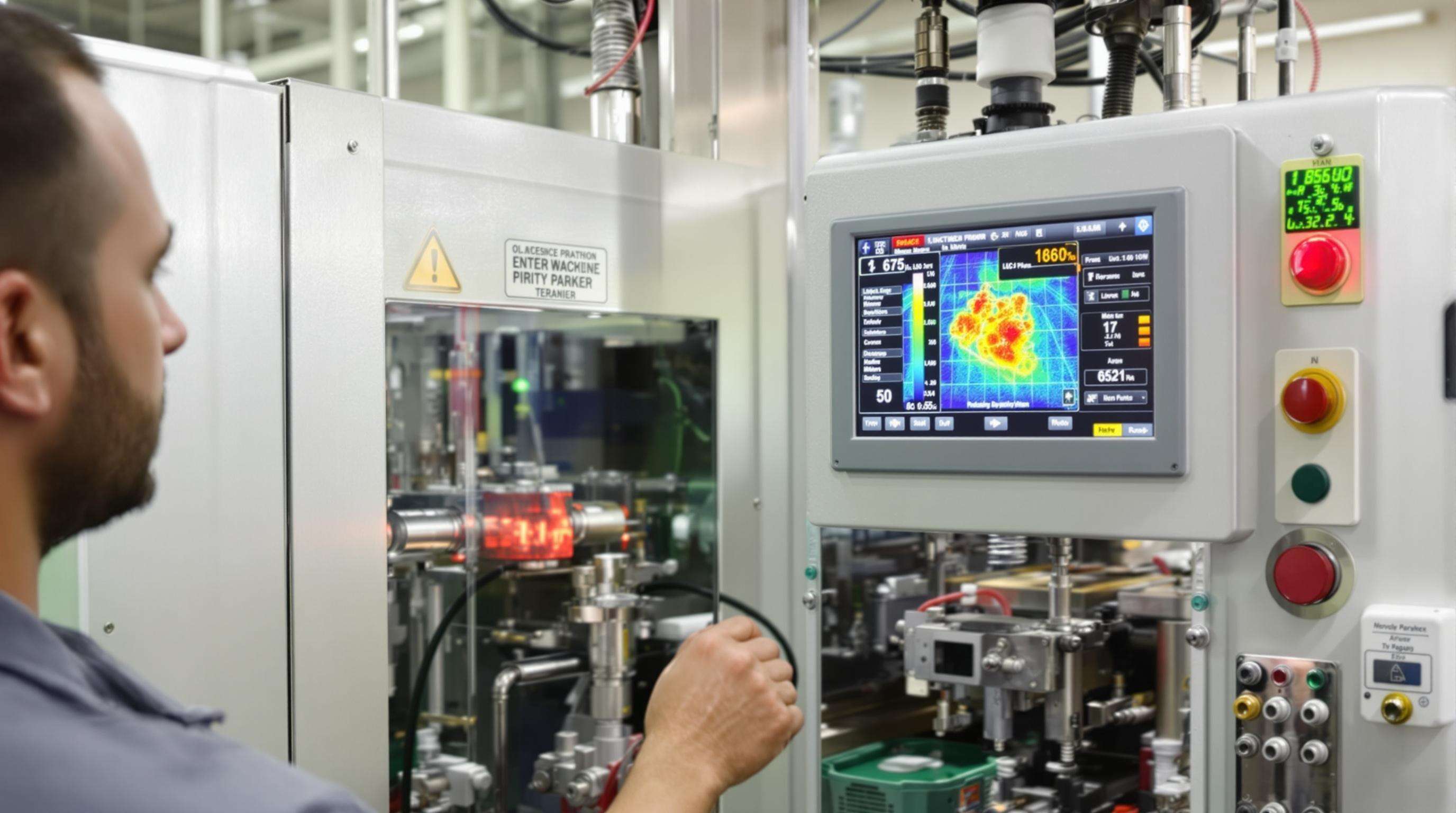

AI-Driven Predictive Maintenance for Bagging Machines

AI transforms maintenance by using data analytics to anticipate failures before they occur. This approach leverages historical patterns and real-time monitoring to optimize interventions, reducing unexpected downtime.

Reducing Downtime with Machine Learning Algorithms

Machine learning analyzes vibration patterns and thermal signatures to identify failure indicators weeks in advance. Plants eliminate 50-80% of unplanned stoppages by replacing parts during planned pauses, extending equipment lifespan while ensuring consistent throughput.

Sensor-Based Failure Prediction Systems

Embedded IoT sensors track component health, alerting operators to issues via centralized dashboards. Manufacturers report 35-40% faster troubleshooting response times, preventing product spoilage and line shutdowns.

Cost-Benefit Analysis of Smart Maintenance

While requiring upfront investment, predictive maintenance delivers $18-24 savings per machine-hour through avoided repairs. New installations typically recover costs within 6-18 months via productivity gains.

Sustainable Automation in Food Packaging

Energy-Efficient Smart Bagging Systems

Modern systems reduce energy consumption through IoT-enabled sensors and variable-speed motors. Adaptive thermal controls cut HVAC energy demands by 12-18% while maintaining ISO 50001 compliance.

Waste Reduction Through Precision Automation

AI-powered systems achieve 99.8% fill accuracy, virtually eliminating spillage. Automated lines reduce plastic waste by 22-30% through optimized material usage. A 2024 Food Packaging Automation Report highlights how machine learning minimizes trim waste while maintaining structural integrity.

Workforce Transformation in Automated Bagging

Human-Machine Collaboration Models

Cobots handle repetitive tasks while operators focus on quality validation. Facilities report 30-minute changeovers when staff manage automation settings directly.

Reskilling for AI-Augmented Packaging Operations

Current training focuses on IoT monitoring and predictive maintenance. Top manufacturers provide 56 annual training hours per employee to address the 45% skill gap in automated environments.

The Productivity Paradox in Smart Packaging

Initial implementation typically causes a 17% productivity dip before stabilizing. Proper rollout yields a 42% net increase after 12 months when combined with workforce adaptation.

Next-Generation Food Bagging Technologies

Blockchain Integration for Supply Chain Transparency

Blockchain creates immutable records of product history from processing to retail. This enhances recall efficiency while building consumer confidence through traceability.

Predictive Analytics for Demand-Driven Packaging

By analyzing market trends, these systems optimize bagging schedules and material requirements - reducing packaging waste by 22% and inventory costs by 18%.

Implementation Challenges for Smart Bagging Systems

Cost-Benefit Analysis of Tech Integration

While promising 18-34% efficiency gains, manufacturers must evaluate payback periods. A 2024 smart packaging ROI study found 62% of mid-sized processors break even within 3 years.

Legacy System Compatibility Concerns

Retrofitting older machines requires customized solutions that can increase costs by 15-22%. Industry reports recommend phased upgrades to mitigate downtime risks exceeding $740k monthly.

FAQ

What is the role of AI in food bagging machines?

AI vision systems play a critical role in food bagging machines by automating quality control through advanced defect detection.

How does IoT improve food packaging operations?

IoT connectivity allows networked sensors to create interconnected packaging systems, enabling proactive decision-making and reducing food spoilage.

What are the benefits of using robotics in food bagging systems?

Robotics in food bagging systems increase precision and throughput, reduce human error, and facilitate quick recalibration between product formats.

Why is predictive maintenance important in bagging machines?

Predictive maintenance uses data analytics to anticipate failures, optimize interventions, and reduce unexpected downtime, ultimately extending equipment lifespan.

How does automation support sustainability in food packaging?

Automation supports sustainability by reducing energy consumption, minimizing waste, and improving material usage efficiency in food packaging operations.

What challenges are faced in implementing smart bagging systems?

Cost-benefit analysis and legacy system compatibility concerns are significant challenges in implementing smart bagging systems.

Table of Contents

- Smart Tech Integration in Food Bagging Machines

- Robotics Automation in Food Bagging Systems

- AI-Driven Predictive Maintenance for Bagging Machines

- Sustainable Automation in Food Packaging

- Workforce Transformation in Automated Bagging

- Next-Generation Food Bagging Technologies

- Implementation Challenges for Smart Bagging Systems

-

FAQ

- What is the role of AI in food bagging machines?

- How does IoT improve food packaging operations?

- What are the benefits of using robotics in food bagging systems?

- Why is predictive maintenance important in bagging machines?

- How does automation support sustainability in food packaging?

- What challenges are faced in implementing smart bagging systems?