Automatic Vacuum Packaging Machine | MRZK10 P Series

The MRZK P Series is a premade pouch vacuum packaging machine developed by our company.

- Overview

- Recommended Products

Product Details

It combines automatic bag feeding, vacuuming, heat sealing, and bag flattening in one smart system.

This machine is specially designed for products that require a flat and neat appearance after packaging.

Its key feature is the professional flattening function.

Using either a mechanical press plate or an airbag flattening system, the machine presses the bag after vacuuming to remove wrinkles inside the pouch.

It is especially suitable for sauces, meats, and other soft or easily deformed products, helping to create a clean and uniform look for better shelf appeal.

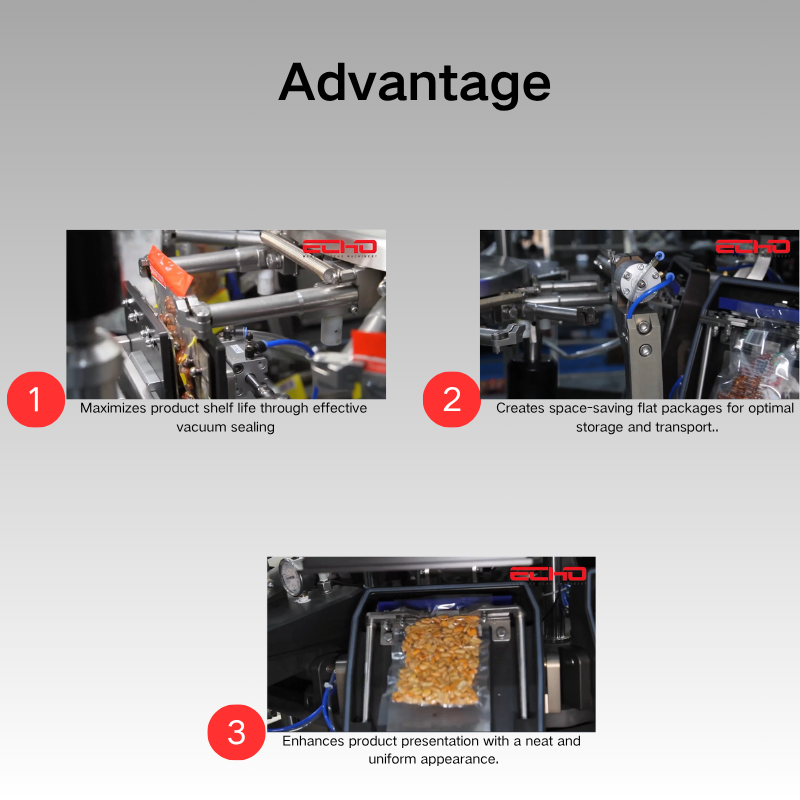

Product Advantages

Dual-Rotary System

The machine includes two rotating parts—a filling system and a vacuum system.

The vacuum chamber rotates continuously, improving speed and efficiency.

Quick Bag Size Change

The bag feeding system supports one-touch automatic width adjustment, allowing fast switch between different bag sizes.

Food-Grade Safety Standards

All parts in contact with materials or bags are made from 304 stainless steel or food-safe materials, meeting international hygiene standards and ensuring food safety.

Easy to Operate

Features a high-end electrical control system with a user-friendly touchscreen.

If a bag is not filled, it will not be sealed and will be automatically removed, reducing waste.

Sealing Temperature Monitoring

The machine monitors the sealing temperature in real time.

If the heating plate is damaged, the system will show an alarm on the screen.

Uses instant heating and water cooling for smooth and secure seals.

Durable Vacuum Chamber

The vacuum chamber is made from aerospace-grade aluminum, precisely CNC machined for strong sealing and long-lasting durability.

Dual-Rotary System

The machine includes two rotating parts—a filling system and a vacuum system.

The vacuum chamber rotates continuously, improving speed and efficiency.

Quick Bag Size Change

The bag feeding system supports one-touch automatic width adjustment, allowing fast switch between different bag sizes.

Food-Grade Safety Standards

All parts in contact with materials or bags are made from 304 stainless steel or food-safe materials, meeting international hygiene standards and ensuring food safety.

Easy to Operate

Features a high-end electrical control system with a user-friendly touchscreen.

If a bag is not filled, it will not be sealed and will be automatically removed, reducing waste.

Sealing Temperature Monitoring

The machine monitors the sealing temperature in real time.

If the heating plate is damaged, the system will show an alarm on the screen.

Uses instant heating and water cooling for smooth and secure seals.

Durable Vacuum Chamber

The vacuum chamber is made from aerospace-grade aluminum, precisely CNC machined for strong sealing and long-lasting durability.

Product Parameters

| Parameter | MRZK10 201P | MRZK10 300P |

|---|---|---|

| Package Size | Width:100-200 mm Length:150-300 mm | Width:180-300 mm Length:200-400 mm |

| Speed | 10-50 bags/min | 10-30 bags/min |

| Weight | 3000 kilograms | 3500 kilograms |

| Size | 2800*2500*1800 millimeters | 3500*2500*1900 millimeters |

| Power Supply | Three phase 380V 50HZ 7.5KW | Three phase 380V 50HZ 8.5KW |